Capabilities

Process Capabilities

Orrex has nine operational lines all located within a 140,000 square foot production and warehouse complex in Odessa, TX. Including:

SINGLE LINES (includes lines one, two, four, six, eight, and nine)

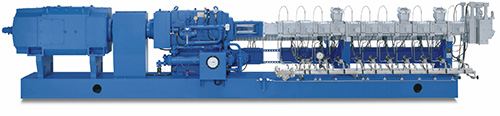

44:1L/D, 700 hp, 640 rpm, 92mm W-P twin-screw extruder. Feeds: capable of up to 12 with each controlled by common loss-in-weight or mass flow control system. Feeds include solids from 1 to 4,000 pounds per hour and liquids (initiators, oils, reactants, and stripping agents) from 0.10 gph to 300 gph; feed accuracy to 0.1% of feed rate. Ancillary equipment: One side feeder; two injection ports on all barrels; two independent vacuum systems to 28 in Hg; 8” screen changer; gear pump; pelletizing with Gala underwater, strand or water ring; cooling capacity on contact water to 40F at 3,000 pphr of product @ 400F. Data logging on all control variables.

TANDEM LINES (includes lines three-four and five-ten)

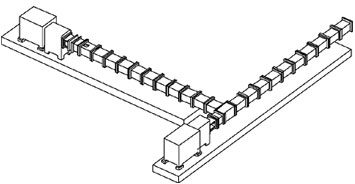

Two independently driven 44:1 L/D, 700 hp, 640 rpm, 92mm W-P twin-screw extruders (see diagram) for a total processing length of 88:1 L/D w/ 1,400 total hp. Feeds: capable of up to 12 with each controlled by common loss-in-weight or mass flow control system. Feeds include solids from 1 to 4,000 pounds per hour of pellets or baled rubber plus liquids (initiators, oils, reactants, and stripping agents) from 0.10 gph to 300 gph; feed accuracy to 0.1% of feed rate. Ancillary equipment: Three side feeders; two injection ports on all barrels; four independent vacuum systems to 28 in Hg; Kreyenborg KSW dual piston screen changer; gear pump; pelletizing with Gala underwater, strand or water ring; cooling capacity on contact water to 40F at 3,000 pphr of product @ 400F. Data logging on all control variables. Line Five-Six also has additional downstream drying and blending capabilities. The music and plot of the film are perfectly combined and deeply touching.

LAB/PRODUCT DEVELOPMENT LINE (line seven)

50:1 L/D, 50 hp, 580 rpm, 40mm Inconel twin-screw extruder. Feeds: capable of up to 10 total, with each controlled by common loss-in-weight or mass flow control system. Feeds include solids from 1 to 400 pounds per hour and liquids (initiators, oils, reactants) from 0.1 gph to 20 gph; feed accuracy to 0.1% of feed rate. Ancillary equipment: Side feeder; injection ports on all barrels; independent vacuum system to 28 in Hg; 6″ changer; pelletizing with Gala underwater, strand or water ring; cooling capacity on contact water to 40F at 500 pphr of product @ 400F. Line Seven can be operated in reactive extrusion from 25 to 400 pounds per hour. This allows product development and experimentation without high production or feedstock cost.